Explore the latest innovations in Slopehelper technology, designed to handle grass cutting, pruning, and spraying with unmatched accuracy and sustainability.

Explore the latest innovations in Slopehelper technology, designed to handle grass cutting, pruning, and spraying with unmatched accuracy and sustainability.

The Drum Mulcher has emerged as an Innovative tool in the world of agriculture and land management, offering unparalleled efficiency in cutting, mowing, and mulching. Designed with innovation and practicality in mind, this versatile attachment is the ideal solution for tackling grass, branches, and other vegetation. Its modern design and unique features not only improve […]

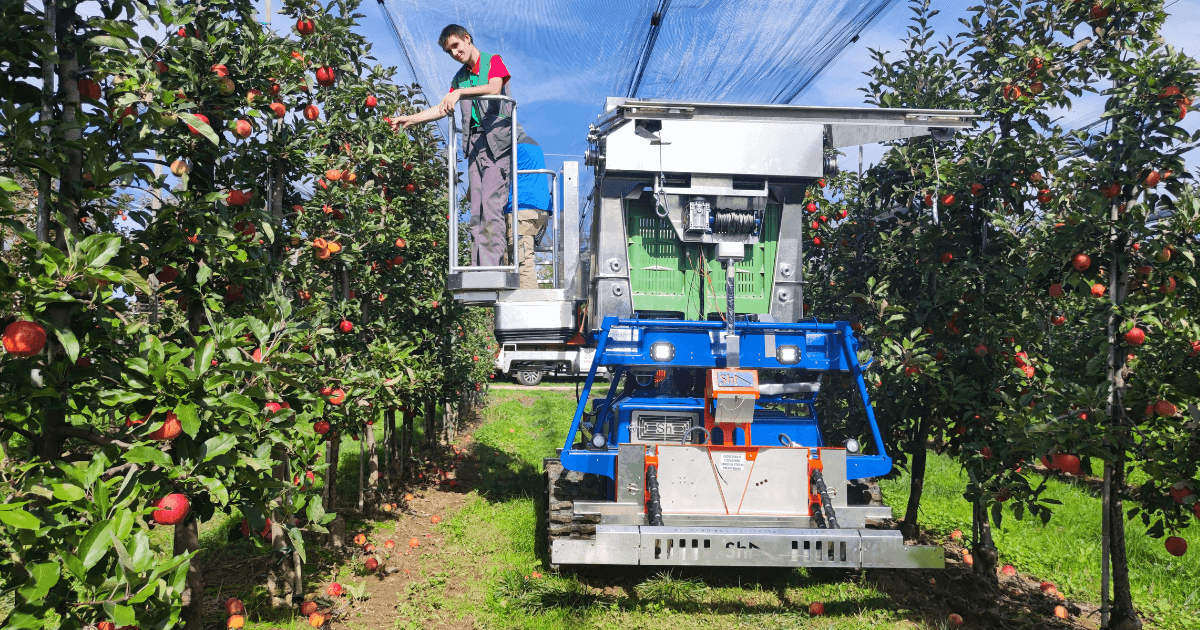

When it comes to fruit harvesting, efficiency and cost-effectiveness are crucial for plantation owners and farm operators. The Harvesting System for fruit harvesting introduces an innovative solution designed to revolutionize how plantations manage their harvest season. With its multilevel harvesting shelves, this system combines practicality, adaptability, and affordability to streamline operations while enhancing productivity. An […]

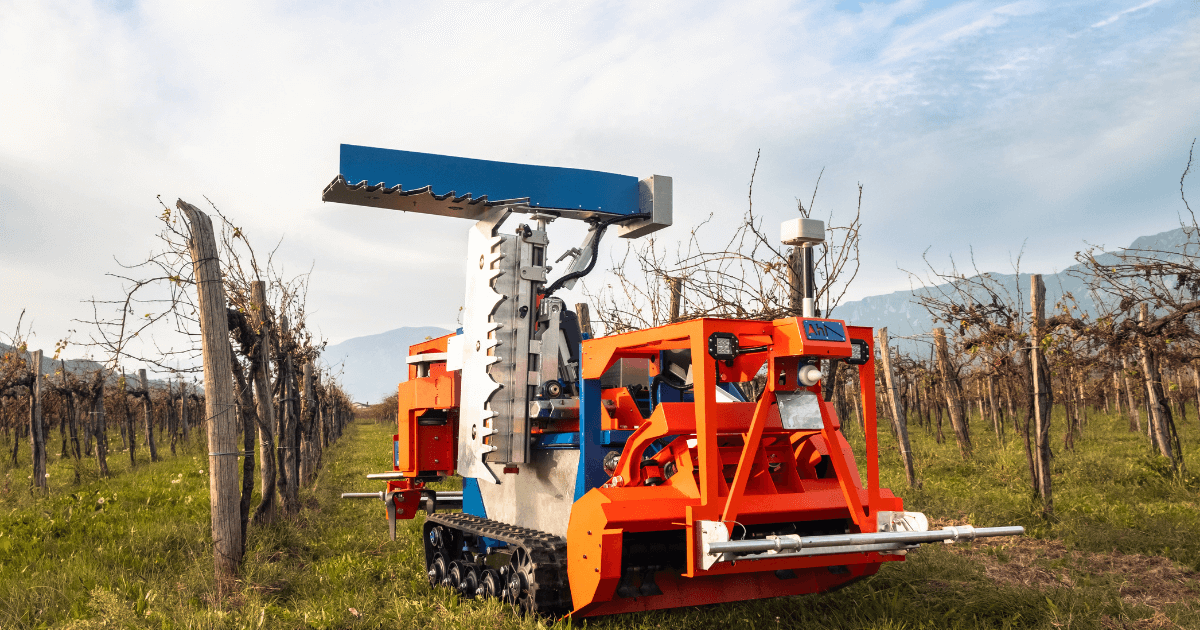

Revolutionizing Autonomous Pruning Precision, efficiency, and adaptability are essential in modern agriculture. With advancements in technology, agricultural machinery is evolving to meet the demands of large-scale and specialized operations. One groundbreaking development is the Horizontal and Vertical Cutter, a game-changing tool for orchard and vineyard management.Designed for maximum flexibility and efficiency, this cutter combines cutting-edge […]

The agricultural world is experiencing a profound transformation, driven by cutting-edge technology. As the global population swells, the demand for food production rises sharply, placing unprecedented pressure on farmers to cultivate more sustainably and efficiently. Enter autonomous agriculture technology—an innovative frontier that is revolutionizing farming through drones, robotic systems, and autonomous tractors. Let’s explore how […]

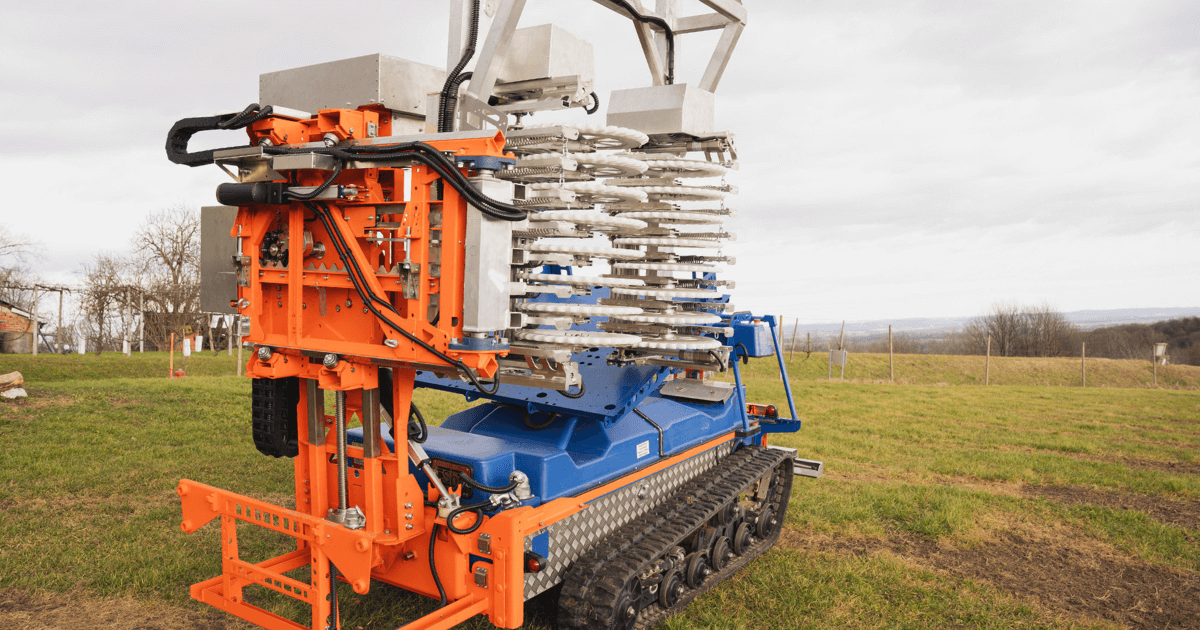

Blossom thinning is a crucial horticultural practice that optimizes fruit quality, improves tree health, and ensures consistent annual yields. By selectively removing excess flowers, growers can focus the tree’s resources on fewer fruits, resulting in larger, sweeter, and more desirable produce. With advancements in agricultural technology, innovative tools like the Blossom Thinner have revolutionized the […]

Explore the latest innovations in Slopehelper technology, designed to handle grass cutting, pruning, and spraying with unmatched accuracy and sustainability.

Explore the latest innovations in Slopehelper technology, designed to handle grass cutting, pruning, and spraying with unmatched accuracy and sustainability.

What to Expect with Robotic Farming Tools? Preparing for the Future of Orchard Management As farming practices continue to evolve with new technologies, many orchardists are exploring the benefits of robotic farming solutions. Though the idea of using robots like the Slopehelper may seem futuristic, it’s becoming increasingly relevant as the demand for efficiency, precision, […]

In the world of modern viticulture, efficiency and precision are key to maintaining high-quality vineyards. Introducing Agilehelper—a revolutionary autonomous agricultural robot designed to streamline vineyard management. Whether you are looking for precise pruning, weed control, or optimized spraying, Agilehelper offers an all-in-one solution tailored for vineyard operators. With its two specialized models—the Grassfighter and the […]

Located in Logatec, Slovenia, PeK Agroline stands as the agricultural division of PeK Automotive, a company dedicated to pioneering technological advancements across industries. As one of PeK Automotive’s three specialized branches, PeK Agroline is at the forefront of agricultural innovation, offering farmers an unprecedented leap into the future with its cutting-edge robotic solutions. For centuries, […]