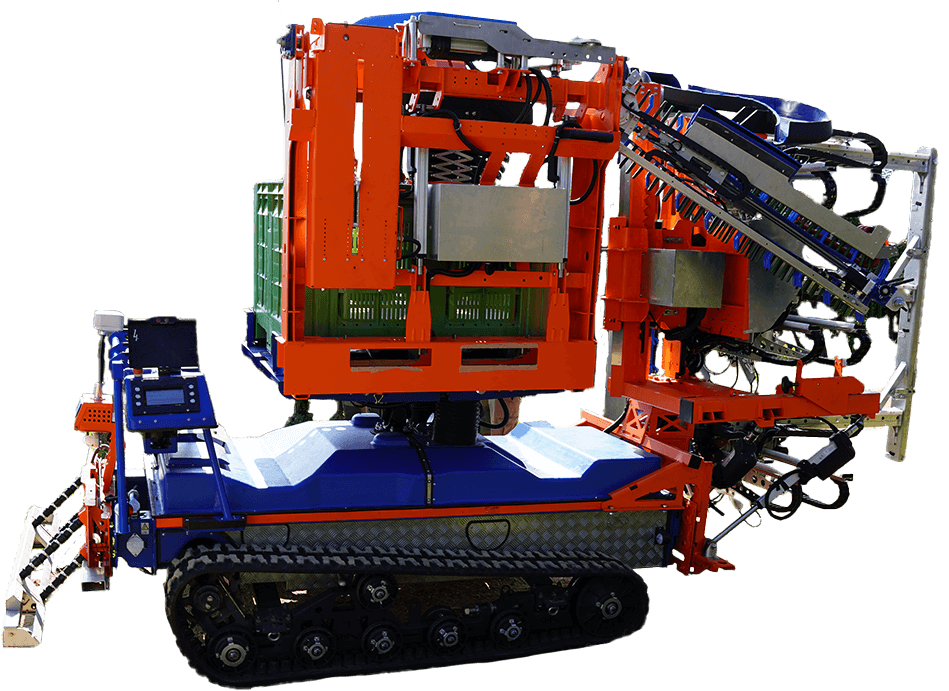

Autonomous fruit picking by 6 robotic manipulators

This cutting-edge harvesting instrument offers an up to 8-fold reduction in costs for one of the most labor-intensive agro-cycle operations in fruit plantations—harvesting. These unmatched cost savings are achieved by replacing 8 seasonal workers with a fully robotic solution.

100% Autonomous | 100% Electric

The system consists of two key modules:

- 1

The Fruit Distribution Module, installed on the gravity-stabilized platform of Slopehelper, ensuring stable and efficient handling of harvested fruit.

- 2

Harvesting Block, attached to the rear of the base platform, featuring six horizontally shifting robotic manipulators equipped with Computer Vision for fruit detection and harvesting. These manipulators are mounted on a guided sliding frame, which moves vertically up and down to adjust the working area and optimize harvesting efficiency.

Fruit Distribution Module

Harvesting Block

This advanced robotic harvesting solution maximizes productivity, efficiency, and cost-effectiveness, making it a game-changer for modern fruit plantations.

Robotic Automation: How Much Can You Save with the Fruit Picker?

Discover the real-life calculation below, based on results from an actual orchard.

The following calculations provide an overview of the time and effort required for harvesting using the Slopehelper and manual picking methods.*

Calculation for Slopehelper is done as follows:

- Calculate the amount of harvest per wave based on the productivity and field area

- Calculate the amount of harvest per row side based on geometry and productivity

- Estimate number of passes through one passage based on the harvest size and bin capacity

- Calculate harvesting time based on the fruit picker productivity and the amount of harvest

- Calculate travel distance without harvesting based on number of passes, length of the row and length of harvested

- Calculate travel time

- Calculate time required for harvesting a passage based on harvest time, travel time, unloading time and row change time

Calculate for manual picking is done as follows:

- Calculate the amount of harvest per wave based on the productivity and field area

- Calculate the harvesting time based on the amount of workers, workers productivity and amount of harvest

- Calculated the additional time based on the geometry of plantation and rotation time

Create your own calculation using your field data and actual conditions.

Features & Benefits

The Slopehelper Fruit Picker, combined with the Slopehelper Base Platform, operates with complete autonomy, eliminating the need for an operator to manage platform driving, supervision, or harvesting control.

With this system, a single operator can oversee the entire plantation, only handling bin loading and unloading using a forklift. Instead of relying on a large seasonal workforce, just one operator per shift (two per 24 hours) is required to manage the entire field’s harvesting process.

This revolutionary automation drastically reduces labor dependency and costs, ensures continuous high-efficiency harvesting, and maximizes productivity with minimal human intervention.

The Fruit Picker is a high-efficiency robotic harvesting instrument designed to replace a team of 8 seasonal workers, significantly reducing labor costs and dependency on human workforce availability.

This system can harvest a full bin (approximately 450 kg of 80mm apples) in just 1 hour, ensuring unmatched productivity. While comparing to human labor, it’s crucial to note that the Slopehelper Base Platform requires only 3 hours for recharging. Unlike human workers, Fruit Picker doesn’t take breaks, smoke, eat, or get tired, operating effortlessly 16 out of 24 hours, which no human team can match.

This fully autonomous, high-performance harvesting solution ensures continuous operation, maximum efficiency, and a substantial reduction in harvesting costs, making it an indispensable tool for modern fruit plantations.

The Fruit Picker is an autonomous harvesting system designed for damage-free collection of semi-spherical fruits, including apples, peaches, pears, avocados, oranges, lemons, and more.

Equipped with Computer Vision and six human-hand-like ergonomic robotic manipulators, the system precisely identifies, reaches, and picks fruit with optimal grip and movement control, ensuring a gentle harvesting process that prevents bruising or mechanical damage.

For citrus harvesting, the Fruit Picker features specialized gripping cups that execute a final rotational movement at the detachment stage, mimicking the natural hand-picking process and ensuring a clean, efficient fruit separation from the tree.

This advanced, crop-adaptive technology maximizes harvest quality and efficiency, making it an ideal solution for modern high-density fruit orchards.

The Fruit Picker is designed for versatile harvesting, capable of operating in both super-intensive and conventional intensive plantations. Its advanced Computer Vision, optimized manipulator length, and kinematic design allow it to adapt seamlessly to different orchard structures.

This means fruit growers can implement the robotic system without additional plantation adjustments, enabling effortless integration into current farming practices while maximizing harvesting efficiency.

The Fruit Picker replicates the complex motor functions of the human hand, which requires at least six axes of movement for tasks like harvesting citrus fruits. Such precision is highly complex and can only be achieved through deep integration of advanced electronics and kinematics.

Leveraging 30 years of expertise in defense technology and special telemechanics, our team has developed a unique, highly reliable system using Commercial Off-The-Shelf electronics electronics and precision kinematics. The Fruit Picker incorporates nearly 50 axes, controlled by electromechanical actuators and high-performance brushless motors, ensuring seamless operation in rugged field environments.

This cutting-edge robotic system is designed for true field conditions, delivering unmatched accuracy, durability, and efficiency in automated fruit harvesting.

The Fruit Picker, like all Slopehelper Agrosystem instruments, operates exclusively on electromechanical solutions, without relying on hydraulic or pneumatic actuators. Unlike many startup-developed apple-picking prototypes that still use hydraulics or pneumatics, the Slopehelper Fruit Picker is engineered for maximum reliability and energy efficiency.

By eliminating fluid-based systems, this robotic harvester offers:

- Higher durability – No risk of leaks, pressure failures, or maintenance-intensive components.

- Superior energy efficiency – Optimized power consumption, extending operational runtime.

- Precision and control – Smooth, accurate movements that replicate human-like picking actions without mechanical delays.

This robust electromechanical design ensures the Fruit Picker is a fully field-ready, highly efficient, and long-lasting solution for modern fruit harvesting.

The Fruit Picker is specifically designed for stable and precise operation on slippery surfaces. Special actuators dynamically adjust the manipulator frame inclination, ensuring that the robotic arms remain perfectly aligned with the green fence and crop, regardless of terrain conditions.

Additionally, the self-stabilizing cargo platform of the Slopehelper ensures that the agro bin remains in a constant horizontal position, preventing harvested fruit from shifting or sustaining damage due to uneven or slippery terrain.

In fruit harvesting, selective picking is crucial to ensure that only fully ripened, market-ready fruits are collected. Unlike seasonal workers, who may lack consistency and responsibility for plantation quality, the Slopehelper Fruit Picker guarantees 100% accuracy and reliability in its harvesting process.

Equipped with Computer Vision-based color gradation and laser-net size measurement, the system ensures that only fruits meeting the optimal ripeness and size criteria are harvested. This automated selection process allows:

- Maximize profitability.

- Maximize profitability offering.

- Avoid premature harvesting, ensuring fruits reach full market value.

- Enhance overall plantation efficiency, reducing post-harvest sorting efforts.

By combining AI-driven precision and automation, the Slopehelper Fruit Picker revolutionizes orchard management, delivering consistent quality and increased financial returns.

Technical Specifications

Height

Length

Width

Weight of attachment

Weight with installed attachment

Maximum height of harvesting

Minimum height of harvesting

Maximum depth of harvesting

Maximum slope angle

Number of manipulators

Picking speed

Fruit size

Operation speed

Compatibility

Drive method

Number of belts

Motor

Estimate Your Investment

Calculate Your Savings with Fruit Picker Attachment

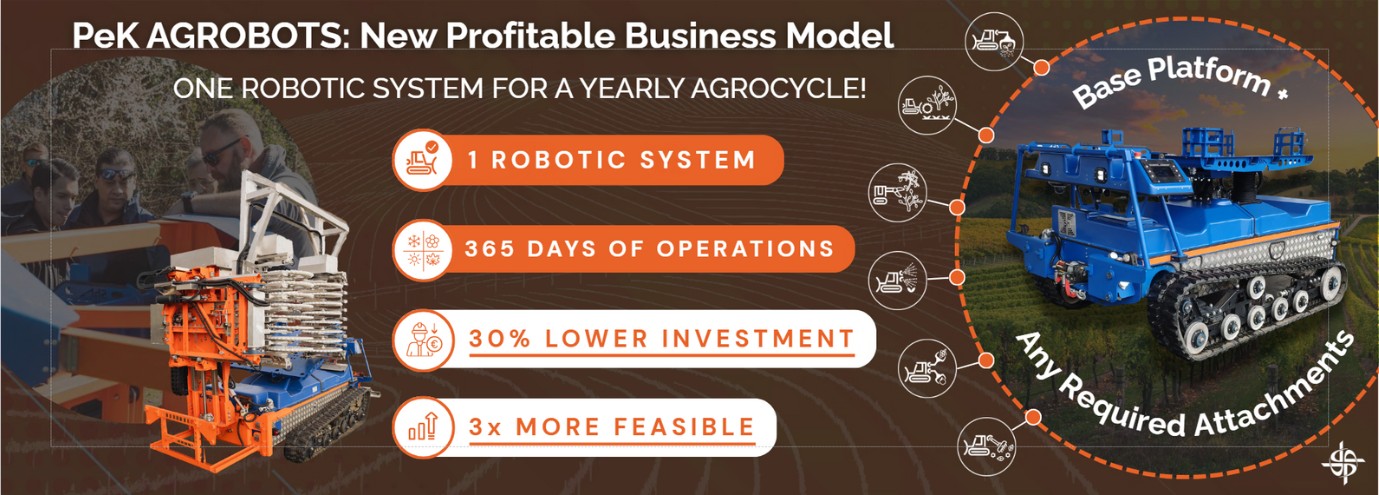

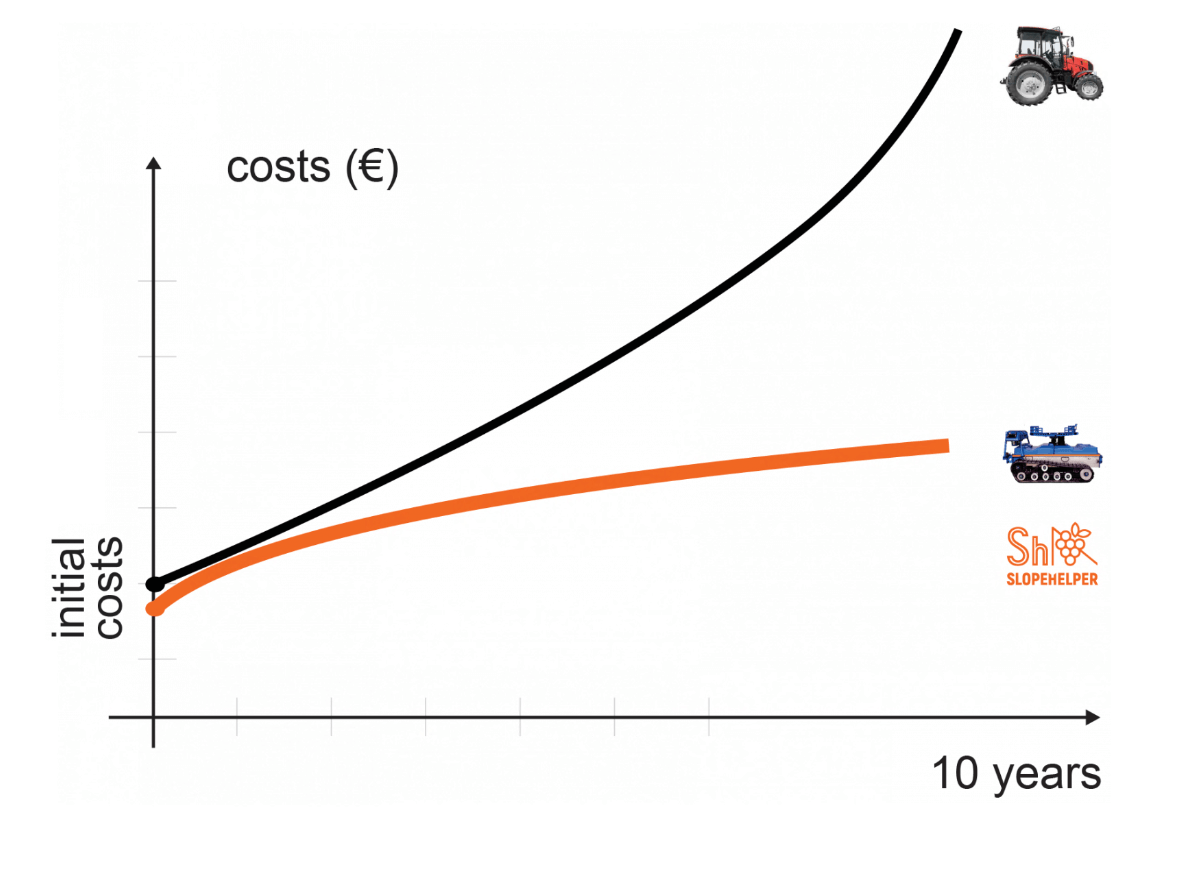

The Slopehelper Autonomous Robotic Agrosystem is a fully electric, low-voltage solution built to transform orchard and vineyard operations. In comparison to traditional tractor-based methods, Slopehelper delivers:

- Up to 3x lower operational costs

- Significantly reduced initial investment

- Fully autonomous performance that reduces labor requirements

With a progressive, cost-efficient approach, Slopehelper ensures long-term savings and operational efficiency.

Use Attachment Fruit Picker in our Feasibility Calculator to estimate your investment and calculate how much you can save.

Smarter, Faster, and More Efficient Than Conventional Harvesting

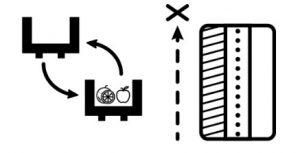

The Fruit Picker revolutionizes orchard harvesting by efficiently collecting fruit along one side of each tree row. Often, the harvested quantity exceeds a standard bin’s capacity, requiring strategic unloading. Unlike manual platforms, which swap bins mid-row, the Slopehelper Fruit Picker completes the row smoothly—full bins are replaced at the end with a forklift, minimizing downtime and maximizing productivity. With careful planning, growers enjoy higher efficiency, smarter operations, and a faster harvest.

The Limits of Conventional Harvesting

Bin Capacity Limit

Normally the fruits which can be collected on one side of the tree row doesn’t fit into the standard agricultural bin.

End-of-Row Unloading

The only option for unloading the full bin is to drive the machine until the end of the passage, where it can be taken out by a fork lift and replaced by an empty one.

Travel Time Consideration

This movement with a full basket will take time and not contribute to the operation, so the strategy must be selected wisely.

Slopehelper Fruit Picker Saves All the Limits

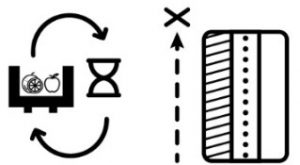

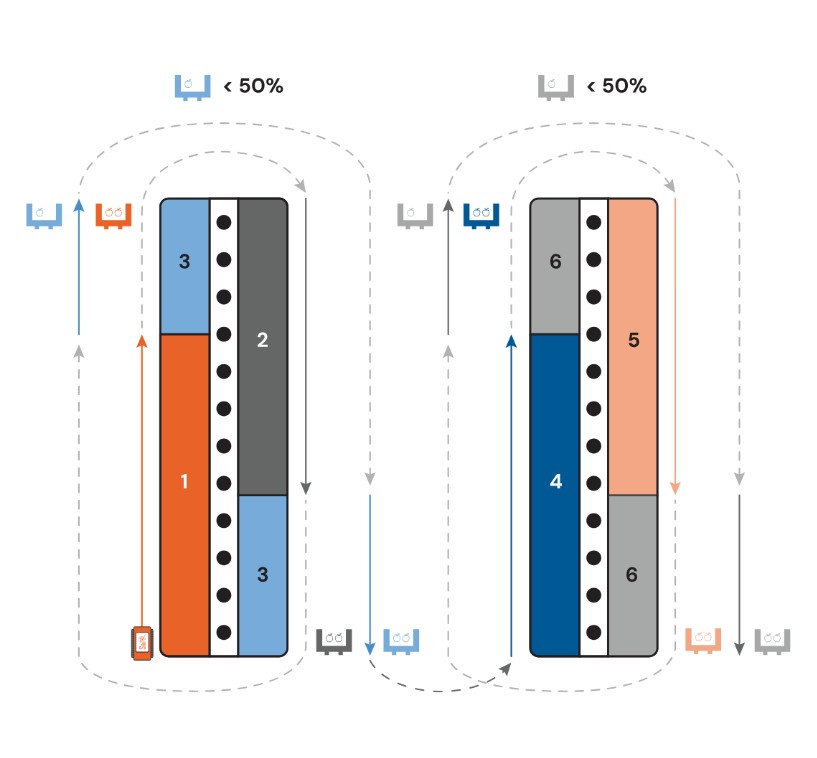

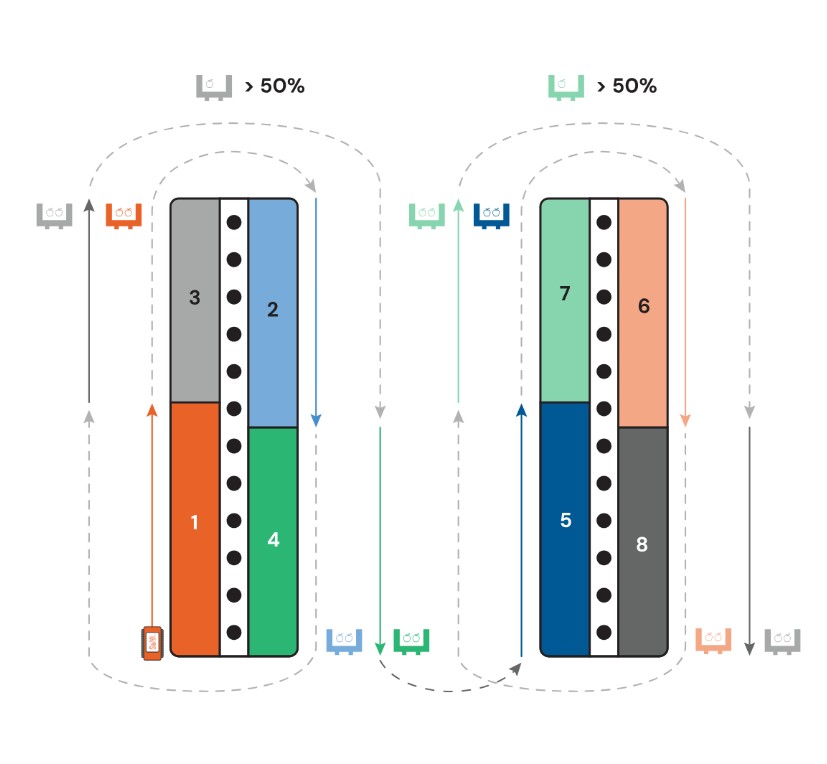

The Fruit Picker overcomes the limitations of traditional harvesting by minimizing idle travel time and optimizing bin unloading. When the basket is full, the machine efficiently moves to the unloading point and resumes work with minimal disruption. A smart strategy ensures that partially filled bins continue harvesting when appropriate, maximizing overall productivity. The path and sequence of operations are illustrated below.

Fruitpicker Strategy : The optimized path and smart sequence of operations

With an optimized path, the machine follows a smart sequence that minimizes non-harvesting travel, ensuring maximum productivity.

- Full Bin Handling: When a bin is full, the Slopehelper moves it directly to the unloading point at the end of the passage. After unloading, it immediately continues harvesting in the next passage of the same row.

- Partial Bin Rule: If a row is completed and the bin is less than 50% full, harvesting continues in the next row without unloading. If over 50%, unloading is requested before moving on.

Experience the Future of Harvesting

Apply for a Slopehelper Fruit Picker demo and see how robotic automation can save time, reduce costs, and boost productivity in your orchard.